Washi making that fuses tradition with innovation

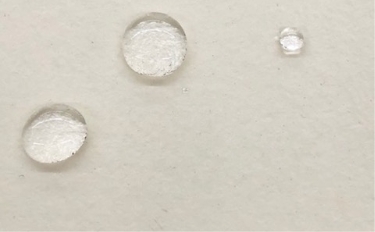

From ancient times, Japanese washi was referred to as “Pure white paper that can reach the gods” and was said “to purify the impure.” We make our washi with between three and seven layers. The outermost layers are always of white washi sheet, added over the multiple inner layers textured with various elements. Behind our craft is the mentality of the craftsmen with their reverence for Japanese tradition and the drive to leave a legacy for the next generation.